Clocks are most useful when they keep accurate time. While very few mechanical clocks are as accurate as modern quartz movements and certainly will never match the absolute accuracy of your cell phone or computer’s USNO Master Clock-synched time, even fairly low-grade mechanical clocks are more than good enough for regular household use if you take a little time to adjust them. Check out this article for basic care and operation of your clock.

The rate of a clock is determined mostly by the length of its pendulum. Several other factors affect the timing of a clock to a smaller degree including the power curve of the clock’s mainspring (fully-wound springs are much stronger than nearly wound-down springs) and environmental factors like temperature and humidity.

It’s relatively straightforward to adjust a clock to correct rate keeping if you have a reference like a cell phone clock to compare against, however this can be very time consuming – especially if you are setting up a new clock that hasn’t been run in a while. You will have to watch the clock over days or weeks to fine-tune its rate. Technology has come to the rescue! The Adams Brown TimeTrax 185 timer is a relatively low cost device that listens to the escapement of the clock and reads the clock’s beat rate on a display. With nearly immediate feedback, you can make repeated rate adjustments and see their effect in minutes rather than days.

How it Works

Electronic timing machines like the TimeTrax or the more expensive but more sophisticated Microset use a piezo electric microphone very similar to a guitar pickup to detect the tick/tock of the escapement. The time between the ticks is counted against an internal quartz oscillator and the resulting BPH – beats per hour – is displayed on the screen.

Knowing the beat rate your clock is currently running at is only half the battle. What rate should it run at? That depends on the design of the clock. Large clocks like tall case/grandfather clocks often run at 3600 BPH which correlates to one tick per second. Smaller clocks can’t have a meter-long pendulum and therefore are geared to run at a faster beat rate. This article will help you determine the correct beat rate for your clock.

Setup

The TimeTrax’s pickup needs to be clamped onto something metal attached to the movement. For clocks without a center second hand, a winding arbor is generally the easiest place. For clocks with a center second hand, a winding arbor may still be the best place if the second hand is removable. If the center second hand is integral to the operation of the clock as it is on some pinwheel regulators, you will need to find something else to clamp to – a movement post or possibly the dial pan (as an alternative, the Microset timer offers an optical sensor that can be set behind the pendulum).

The TimeTrax’s pickup needs to be clamped onto something metal attached to the movement. For clocks without a center second hand, a winding arbor is generally the easiest place. For clocks with a center second hand, a winding arbor may still be the best place if the second hand is removable. If the center second hand is integral to the operation of the clock as it is on some pinwheel regulators, you will need to find something else to clamp to – a movement post or possibly the dial pan (as an alternative, the Microset timer offers an optical sensor that can be set behind the pendulum).

Using the TimeTrax

Once you’ve successfully attached the sensor, turn the TimeTrax on. The TimeTrax includes a beat amplifier that amplifies the sound of the ticks which can be helpful in adjusting the clock to be in beat, but for timing, move the switch to the far right position. After a moment, the device should start counting beats. The red light on the right side of the unit should be flashing with each tick. If the light does not light consistently for each tick or if the light blinks rapidly, the sensitivity needs to be adjusted. Increase sensitivity by turning the gain knob up if the sensor is missing ticks, or turn the gain knob down if the sensor is registering noise as ticks. The sensor is very sensitive to mechanical vibration. Set the TimeTrax down on a stable surface and try not to disturb the sensor cable during measurement.

Once you’ve successfully attached the sensor, turn the TimeTrax on. The TimeTrax includes a beat amplifier that amplifies the sound of the ticks which can be helpful in adjusting the clock to be in beat, but for timing, move the switch to the far right position. After a moment, the device should start counting beats. The red light on the right side of the unit should be flashing with each tick. If the light does not light consistently for each tick or if the light blinks rapidly, the sensitivity needs to be adjusted. Increase sensitivity by turning the gain knob up if the sensor is missing ticks, or turn the gain knob down if the sensor is registering noise as ticks. The sensor is very sensitive to mechanical vibration. Set the TimeTrax down on a stable surface and try not to disturb the sensor cable during measurement.

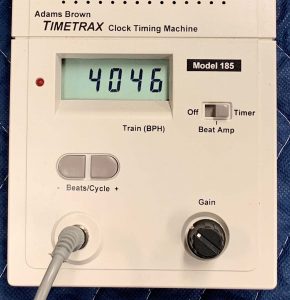

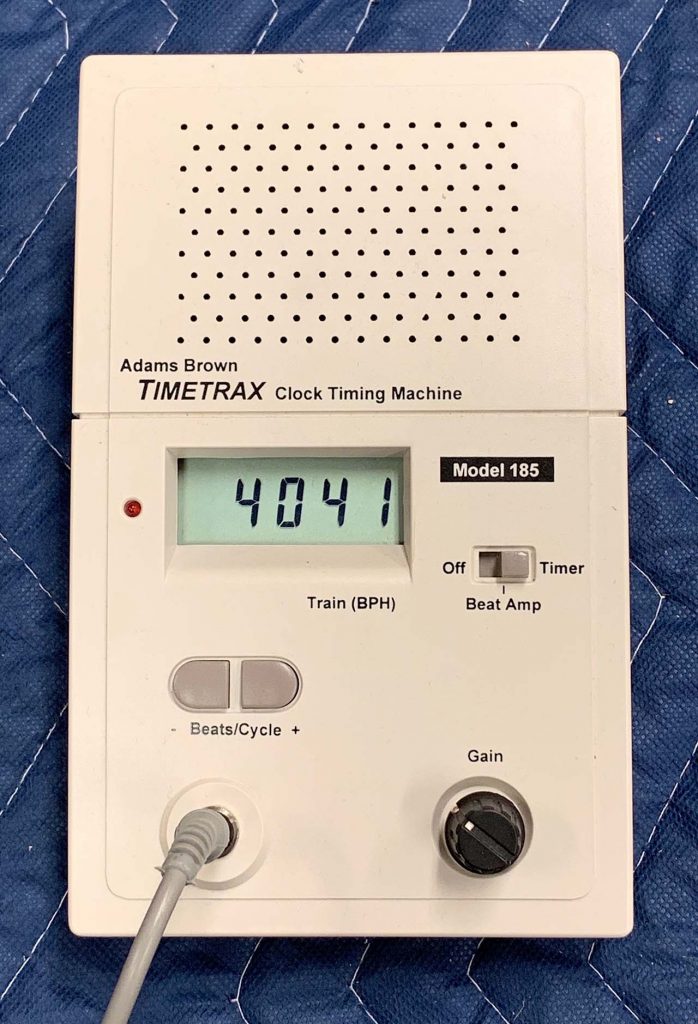

Now that you’re getting good data into the unit, the display will register the instantaneous beat rate of the clock. This number will probably be varying pretty significantly, as the TimeTrax defaults to only averaging the last two ticks and will register every slight imperfection in the time train as a different beat rate.

Now that you’re getting good data into the unit, the display will register the instantaneous beat rate of the clock. This number will probably be varying pretty significantly, as the TimeTrax defaults to only averaging the last two ticks and will register every slight imperfection in the time train as a different beat rate.

There is a trade off with averaging. A small sample size means the display updates frequently, however the reading jumps around. A larger sample size means the display more truly reflects the rate of the clock, however this significantly slows the display update rate as the TimeTrax only updates the display twice per sample set. At high sample rates, this means it may take you a minute to get a new reading.

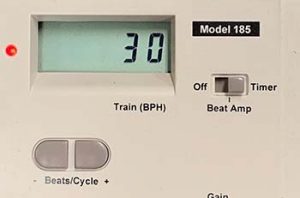

If your clock is running significantly fast or slow, I find that an averaging setting around 10 to 16 beats produces reasonable results with fairly frequent display updates. After I make a couple rounds of pendulum adjustment and get the rate closer to the target, I increase the sample size to around 30 to continue to fine tune.

If your clock is running significantly fast or slow, I find that an averaging setting around 10 to 16 beats produces reasonable results with fairly frequent display updates. After I make a couple rounds of pendulum adjustment and get the rate closer to the target, I increase the sample size to around 30 to continue to fine tune.

If you know how many teeth your escape wheel has, setting the sample size to twice the number of teeth on the escape wheel (each tooth is touched twice per revolution – one tick and one tock) will give you the best balance of accuracy and fast display uptime. A sample size different than twice the number of escape wheel teeth will double-count or under-count errors in the escape wheel, whereas a sample size of twice the number of teeth of the escape wheel will correctly average the whole wheel. Many escape wheels turn once per minute – typically larger clocks. For these clocks the number of teeth on the escape wheel is 1/2 of the BPM rate of the clock. For example, a 4800 BPH/80 BPM clock will normally have a 40 tooth escape wheel, so a setting of 80 beats/cycle fully represents the escape wheel. That’s a good place to start, but your clock may be different. Most smaller clocks with beat rates higher than 80 BPM perform more than one rotation per minute, so the above rule doesn’t apply.

Final Rate Adjustment

Getting your clock to show its rated BPM on the TimeTrax isn’t quite the whole story. The TimeTrax has a resolution of one beat. That gets you to 99.99% of the correct rate, however the TimeTrax will not tell you if your clock is running at 3600.4 BPM or 3599.5 BPM. Over the course of a week this can accumulate to an error of more than 2 minutes.

There is a second factor that can be significant- the state of wind of your clock when you timed it. While weight-driven clocks always have a constant force and therefore a constant rate as the clock winds down, spring-driven clocks run fast when first wound and gradually slow down near the end of their wind. This error can be a couple of minutes as well. The TimeTrax will get you close, but you will need to fine-tune your clock’s rate over a few weeks by comparing it to an accurate reference like your cell phone clock.

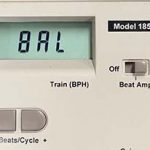

The reading will change with every tick of the clock. A perfectly in-beat clock with a perfect escape wheel will display zero for both the tick and the tock. This is not a realistic situation, as every movement has imperfections causing slight errors. A clock that is reasonably in beat will have numbers in the range of +/- 40 or less. If you’re seeing larger numbers, then your clock is not in beat.

The reading will change with every tick of the clock. A perfectly in-beat clock with a perfect escape wheel will display zero for both the tick and the tock. This is not a realistic situation, as every movement has imperfections causing slight errors. A clock that is reasonably in beat will have numbers in the range of +/- 40 or less. If you’re seeing larger numbers, then your clock is not in beat.

Some clocks have imperfections in their escape wheel such that the clock sounds in beat some of the time and out of beat some of the time. Correcting this requires disassembling the clock and working on the escape wheel – either straightening the arbor or straightening the teeth of the escape wheel.

Putting Your Clock In Beat

A clock that is “in beat” will have evenly-spaced ticks and tocks. Clocks that are significantly out of beat will have a galloping sound. Correcting this depends on the type of clock you have.

The first place to start is to make sure your clock is level. Some wall clocks have beat indicators – a scale at the bottom of the pendulum swing. Tilt your clock until the pendulum (stop the clock) point to the center mark of the scale. For mantle or shelf clocks, you may need to shim one side to make the clock level.

If you are lucky, making the clock level will correct the beat issue, however sometimes further adjustment is necessary. Some clocks such as Vienna Regulators have an adjustment near the top of the pendulum – turn the screw to move the pendulum bob relative to the upper pendulum suspension. Make small adjustments and see if the clock is improving. If it is getting worse, turn the nut in the opposite direction.

Some clocks have a verge that is friction-fit onto the shaft so pulling the pendulum slightly farther than its normal travel in the direction of the short tick can help correct the issue. On other clocks, the crutch wire that connects the verge to the pendulum rod needs to be slightly bent. This may require partial disassembly of your clock and is best done by someone with some experience.

If your clock is slightly out of beat, adjusting the clock’s orientation so it is in beat but not level may be a reasonable compromise and won’t harm the clock. On some clocks that may have lived a bit of a hard life, it might be hard to judge which of the non-parallel sides to use as your level reference anyway.

8 replies on “Timing a Clock With The TimeTrax 185”

where can I buy one to set my new England footless grandfather clock

gary weinberg

You can buy them from Merritt’s Antiques or from Timesavers.

Can the 185 be calibrated, and would you do that. Some of the readings I get on my 185 makes me wonder if the unit is out of calibration. I would appreciate a reply. Thanks bruce

Hello Bruce, thank you for your note. I don’t believe there is any user-accessible calibration in the 185 or other TimeTrax models, but it seems unlikely to me that that would be the issue.

My issues with this device have boiled down to either not picking up all of the ticks, or being too sensitive so it interprets more than one noise as a tick. I have one clock where the escapement is bouncy enough that it doesn’t work at all, as the timer can’t tell the difference between the desirable tick and the escapement bounce.

I would suggest experimenting with placement of your sensor so you get a good strong signal. If your clock does not have a full-face second hand, usually the winding arbor works pretty well, or perhaps a movement plate. Most of the time my sensitivity knob is around 10:00 or so. If you have your knob a lot higher you may be picking up extra junk. Turn the knob down until the light stops blinking reliably, and then raise it just enough so it registers all the ticks.

The other thing is setting the averaging correctly. It is helpful to know how many teeth your escape wheel has and then set the number of averages to match. For example, if you have a seconds-beat clock, set the TimeTrax to 60 so you capture exactly one rotation of the escape wheel. Any number other than twice the number of teeth on the escape wheel will introduce a bit of hysteresis to the reading where it will oscillate between a couple values.

For testing the rate of the TimeTrax itself, you can always clip it to a quartz clock and see if the TimeTrax reads 3600.

Good luck.

Thanks for writing this article. I am a hobbies clock repairer and have had a TT 185 for sometime. I have an old(Plymouth) time and strike that is giving me a particularly difficult time. Escapents are the hardest for me and I am getting some very erratic reading and I never gave much thought to the sensitivity adjustment. I will now try that. Thanks

My time trax keeps didsplaying low bat even with a fully charged battery and no other display so i cant use it, is there a reset , or does it need repair

Good afternoon,

Where can I buy a Timtrax model 185 in Europe.

I live in the Netherlands.

Thank you in advanceHarry

It appears that CousinsUK.com has the Timetrax available.