I just picked up a pair of master clocks. On the left is an International Time Recorder clock – the company that went on to become IBM – dating from 1925, and on the right is a Standard Electric Time from 1918. Both of these clocks have Minnesota connections: the International Time Recording clock on the left came from Harding High School in St. Paul, MN, and the Standard Electric Time on the right came from St. Paul Fire Station No. 24.

Master clocks are fascinating. They served two functions: they drove and synchronized a large number of slave clocks around a large building such as a school or a factory, and they drove the bell system that timed factory shifts and classroom periods.

The earliest electric clocks were similar to spring or weight-driven clocks with a geared time train and escapement, but instead of winding a spring or lifting a weight, electricity was used to wind the clock. This differs from later electric clocks where the hands were driven by an electric motor.

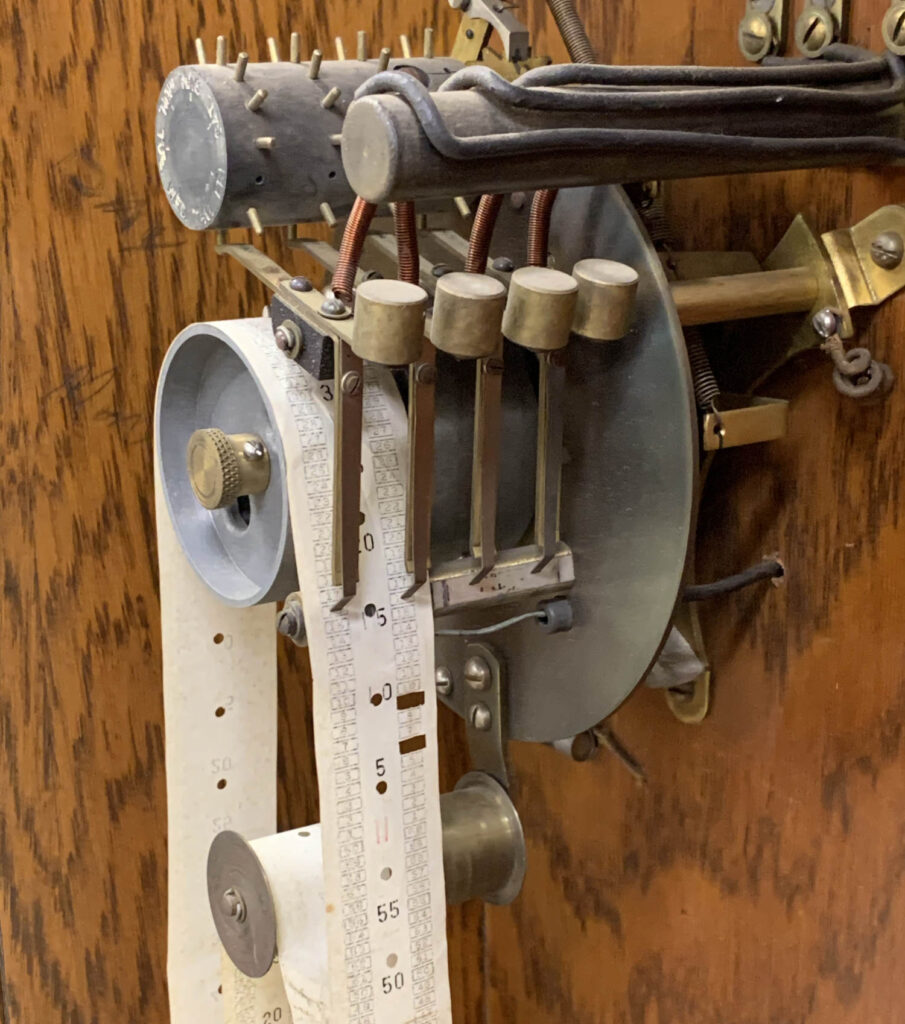

The above picture shows the Standard Electric Time movement and winding mechanism. The reddish cylinder at the bottom of the movement is a solenoid, or electromagnet, that periodically pulls on the winding mechanism, causing the clock to wind a small amount. This clock winds once per minute by advancing a ratcheting wheel one tooth which winds a torsion spring that powers the time train. The clock has a small power reserve of about 45 minutes in the event that power is not available – either during battery changes, or if the clock is powered by building power, for short power outages.

Standard Electric Time

Standard Electric Time was founded in 1884 in Springfield, Massachusetts and was the first US maker of electric clocks. The earliest clocks were powered by dry cell batteries and ran for approximately a year before the batteries needed replacing. The appeal of a reliable clock that doesn’t need winding every week isn’t hard to see.

Ironically, for a clock company named “Standard Electric Time”, their products were not particularly standard; their clock systems were often custom-made for the building, and were engineered for a number of different power systems and the number of slave clocks needed. Because of this, it can take some work to figure out how to safely get a clock operating.

Standard Electric Time made clock systems through the 1970’s, and was purchased by Johnson Controls. The company changed hands a couple times after that.

International Time Recording Company

The International Time Recording Company was founded in 1889 and began making mechanical time recorders – clocks that punched cards to show the time workers arrived and left. They later electrified their product line and produced master clocks that were similar to and competed with the Standard Electric Time clocks.

ITR eventually merged with the Computing-Tabulating-Recording Company, the predecessor of IBM.

Two different bell systems

The International Time Recorder clock has a large brass drum in the center of the clock. This works very much like modern mechanical light timers. Pegs are inserted around the drum which rotates every 6 hours. When the peg makes contact, it triggers a bell relay.

The Standard Electric Time has a paper tape that is punched when the bell is to ring. A feeler rides along the tape, and when it falls through a hole, electrical contact is made and the bell rings.

Slave synchronization

Even the best clocks drift and need correction, and either need winding or some kind of other power source. With a large building and a lot of clocks, this becomes overwhelming quickly. The solution to this is ingenious – slave clocks that don’t actually keep time themselves, but receive a signal from a master clock.

Slave clocks of this era didn’t have a typical clock train with an escapement; instead, the slaves receive an electrical pulse from the master once a minute that fires a solenoid which advances a ratchet mechanism causing the slave clocks to jump ahead one minute. As long as the master clock was managed to keep accurate time, the slave clocks would follow in perfect synchronization.

These are fascinating clocks, and solved a real business problem in an innovative way. Stay tuned as we dig into these and restore them to operational condition.

One reply on “Antique Master Clock Restoration – Project Preview”

I just acquired a IBM master clock similar to the one displayed. It’s in excellent condition, original paperwork, door key, the wood looks like Ash. Can you send a diagram for connecting power.