A preview of the soon to open Cuckoo Clock Museum near Downtown Minneapolis

Categories

Visiting the J Fiorentino Clock Museum

A preview of the soon to open Cuckoo Clock Museum near Downtown Minneapolis

We recently traveled to Duluth and I had a chance to stop in to Security Jewelers to see the Wolf Creek Watch Voyageur in person. For the back story on […]

A pilgrimage to the Midwest’s clock and watch nexus

Mercury seems scary. Can I safely have a mercury pendulum clock?

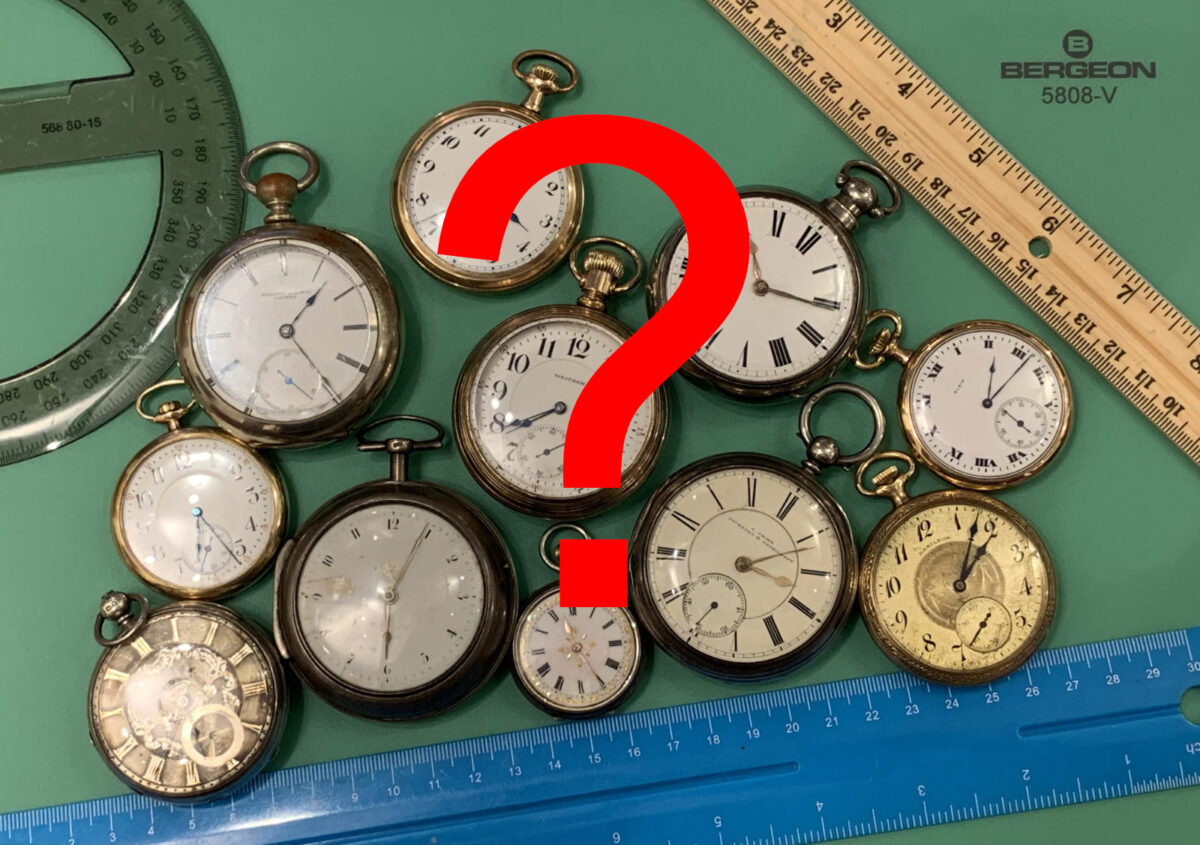

How big is my watch? 18 size? 16 size? How do I know?